A 21-year old kiln needed some love and attention— and some new parts.

When I began using my kiln in 2016, I began keeping a log of the hours that each firing took to achieve a certain cone or temperature. For a few years, the number of hours really didn’t change too much unless the kiln was really loaded but then I noticed that the number of firing hours began creeping up: a bisque firing that would typically take 13 hours began to take 15, then 18, then 20… I then got an error code when the kiln couldn’t ramp up past Cone 3. wtf?? My log was showing me that something was very wrong.

To test it, I fired up an empty kiln to 800 deg F to see if the coils were getting cherry red and found of the 6 coils, only the 2 middle ones were firing! Bits of paper placed on all the coils were charred which told me that electricity was getting to the coils but not getting hot enough to fire pottery to the correct temps. (And —holy crap— let’s just take a moment here to appreciate how amazing it is that a kiln can still get as hot as 1800 deg F with only 2 working coils!!) A pottery mentor advised me that perhaps the thermocouples which act as thermometers of the kiln were probably bad and needed to be replaced. This would be the most logical first step to solving the problem.

However, only a few test firings later, it was apparent that the kiln was still having issues reaching and maintaining the proper temps. In fact, things got worse; the temperature would reach Cone 04 (1840 deg F) but then fluctuate and then start to fall. I called L&L Kilns and the expert there, Rob Battey, suggested that with the age of the kiln, it was likely that the relay switches were worn. A photo of the kiln’s interior confirmed for him that the coils were also quite bad and should be replaced.

So now I was looking at a complete rebuild of my kiln’s guts, which meant that for about $700 I’d practically have a brand new kiln!

While I waited for the new parts to arrive, I set about disassembling the kiln, disconnecting all of the wiring, and removing the aged coils bit by bit with a needle-nosed pliers. This was a royal pain in the butt and took the most time in this whole rebuilding process. So, kids, if you perform proper maintenance on your kiln and replace the coils when you’re supposed to, you can remove the old one in once piece. Who knew? Now you do.

The old and brittle coil pieces partially fill a bucket.

My kiln is a modular one with a computer control unit (the head) and 3 stacked body pieces or ring sections which can be separated. Each region has its own set of coils that heat up and must be disconnected from the contacts in order to be to be replaced.

The disassembled kiln in its 3 sections.

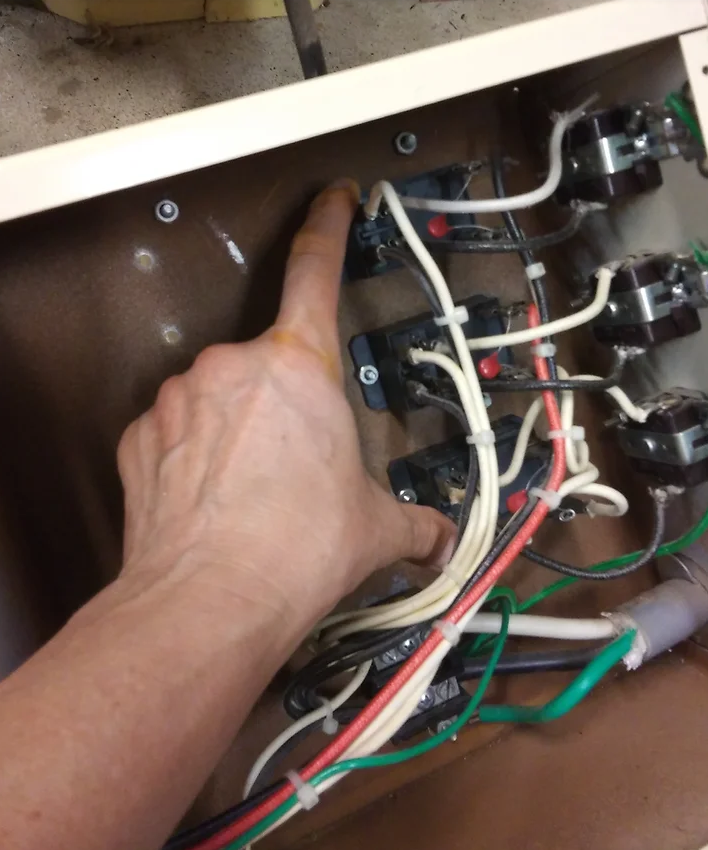

When my parts arrived, I first installed the three new relay switches in the control panel using a fool-proof method of moving one wire at a time from each prong of the old switch to each new prong on the new switch. Then I secured the new relay switch to the inside of the control panel. Plug and play. Snap, snap.

New switch installation was easy-peasy.

The new coils had to be stretched a little bit to the proper length, but installation was a breeze and a lot easier than removal.

Installing new coil in the channel.

I took a photo of the wiring beforehand as my guide which made re-wiring with some new hardware fairly straightforward. Once the wiring was finished, I restacked the kiln segments, reattached the sensor wired to the thermocouples, re-mounted the head unit, plugged it in, and turned the power supply back on. In all, I’d say it took about 3 hours to complete (minus having to run to the hardware store for stainless steel washers).

A pretty straightforward wiring setup.

Test firing the empty kiln at 800 deg F showed all coils glowing cherry red— yay! — proof that the wiring and the coils were properly installed. An empty kiln test fired to Cone 5 properly seated the coils in the channels and the kiln was ready to use.

Big thanks to Rob Battey at L&L Kilns for his amazing customer service and help!

Originally posted on my Kest Pottery blog 22 July 2020 and migrated here in Nov 2022.